Risk Assessments and Supplier Audits

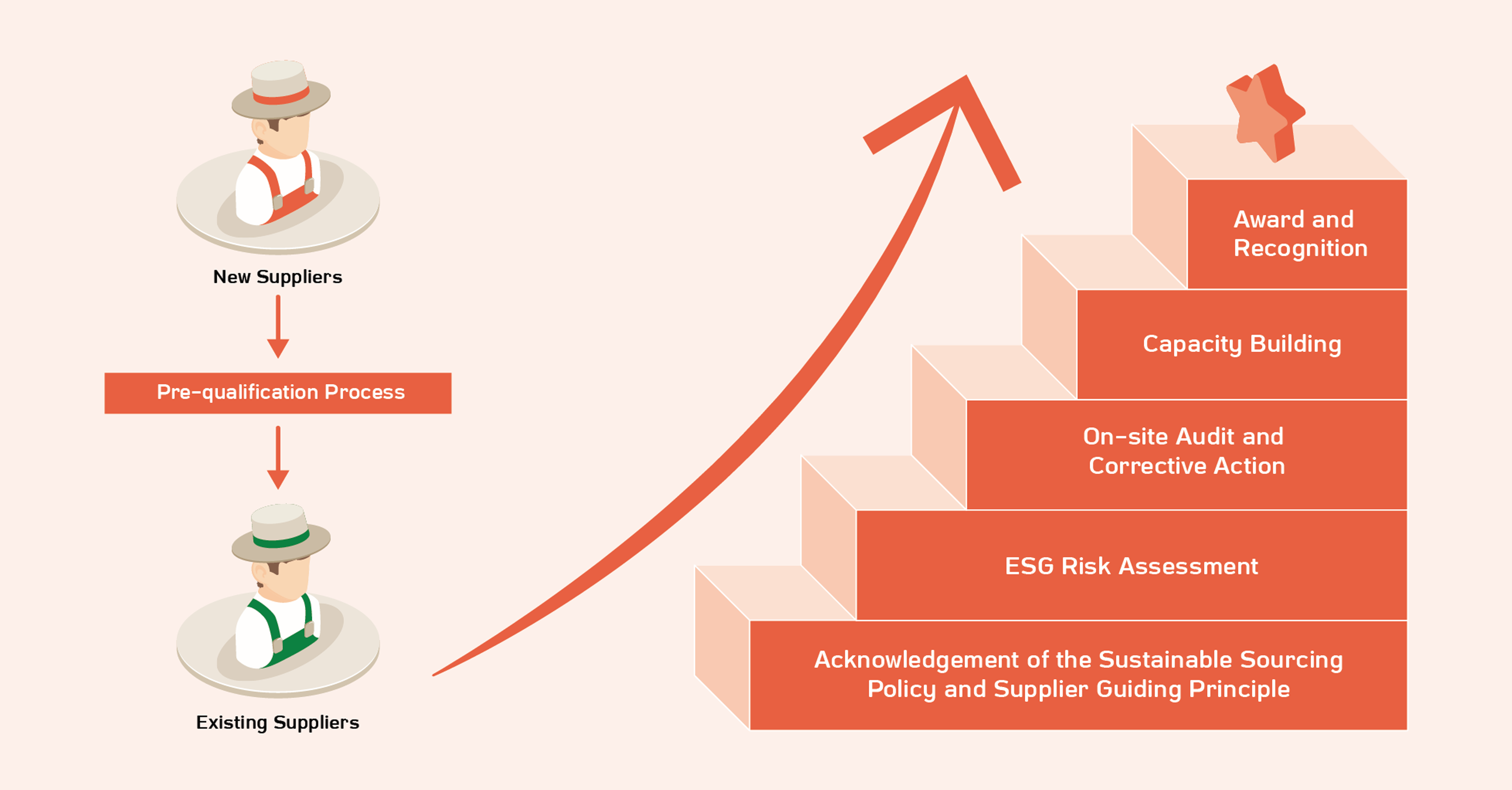

The Company evaluates supplier risks through various processes, including desk research, supplier self-assessment, and on-site audits. Before commencing any transactions with the Company, and upon successful completion of sustainability self-assessment questionnaires, new suppliers are selected based on comprehensive criteria including: the quality of products and services, and sustainability aspects such as traceability and legal compliance.

Existing suppliers must complete sustainability self-assessment questionnaires, which are regularly reviewed under a pre-defined timeframe. The Company has also identified critical suppliers, which refer to those who 1) account for high spending value, 2) supply critical components for our production process, or 3) are non-substitutable or difficult to replace. Self-assessments for critical suppliers are more rigorous, and those that fall under high-risk criteria will undergo on-site ESG audits conducted by Company personnel or independent auditors. The Company also identifies significant suppliers to enhance overall sustainability capabilities.

Remark:

i Reported data covers Thailand and Vietnam operations. Significant suppliers refer to those suppliers identified as having high ESG risk, or critical suppliers, or both.

ii Significant Tier-1 suppliers accounted for 66% of total spend in Tier-1 suppliers.

In 2024, the Company has 859 critical Tier-1 suppliers and 31 critical non Tier-1 suppliers (Thailand and Vietnam operations).

The Company collaborates with suppliers to establish corrective action plans in cases of non-compliance and enhances supplier operations through capacity building activities, while also providing recognition and awards to suppliers with outstanding performance. The supplier risk assessment result in 2024 revealed that the areas needing the most improvement are climate change management, occupational health and safety, and labor practices. The Company is working with these specific groups of suppliers to monitor and improve performance. The Company has also provided training on GHG emission reduction, adaptation to climate change, compliance with good labor practices, as well as, occupational health and safety in the workplace.

The Company integrates ESG considerations as part of the supplier selection process in order to incentivize suppliers towards conducting a sustainable business in line with Sustainable Sourcing Policy and Supplier Guiding Principle, while implementing measures to control ESG risks.

In case suppliers cannot comply with minimum ESG requirements within a set timeframe, a consideration process will be held by relevant committees for possible corrective actions which may ultimately result in exclusion from our vendor list.

The Company has communicated the assessment result to suppliers to promote operational improvement. The communication of comparative ESG performance relative to peers in the same supplier group will be implemented in upcoming years to enhance supplier performance.

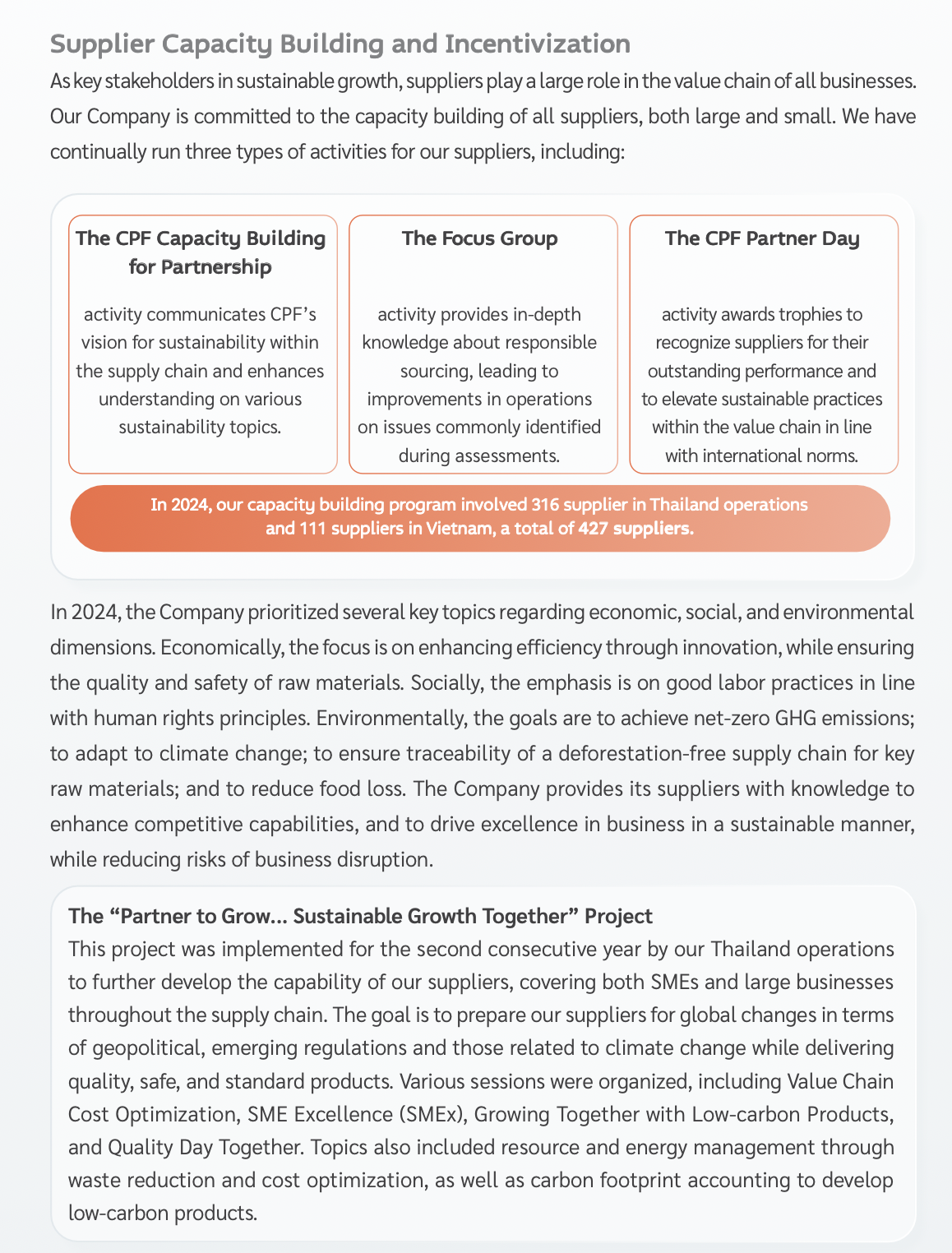

Supplier Capacity Building and Incentivization

As key stakeholders in sustainable growth, suppliers play a large role in the value chain of all businesses. Our Company is committed to the capacity building of all suppliers, both large and small. We have continually run three types of activities for our suppliers, including:

In 2024, the Company prioritized several key topics regarding economic, social, and environmental dimensions. Economically, the focus is on enhancing efficiency through innovation, while ensuring the quality and safety of raw materials. Socially, the emphasis is on good labor practices in line with human rights principles. Environmentally, the goals are to achieve net-zero GHG emissions; to adapt to climate change; to ensure traceability of a deforestation-free supply chain for key raw materials; and to reduce food loss. The Company provides its suppliers with knowledge to enhance competitive capabilities, and to drive excellence in business in a sustainable manner, while reducing risks of business disruption.

CPF Capacity Building for Partnership

This past year, the Company organized the "CPF Capacity Building for Partnership 2024" event in Thailand, providing knowledge regarding net-zero GHG emissions and climate adaptation. The session also included topics related to water efficiency management to cope with floods, droughts, and changes in water quality. Esteemed speakers from the German Agency for International Cooperation (GIZ), Bangkok Bank, and Innovation Idea Co., Ltd. participated in this event, with 110 supplier participants.

Our Vietnam operations organized a capacity-building event titled "Innovation for the Environment: The Role of Supply Chain Partners" to encourage the adoption of technology to sustainably enhance production processes, both environmentally and socially. More than 80 suppliers participated in the event, along with representatives from the Department of Natural Resources and Environment of Dong Nai Province.

Focus Group

Following the announcement of the Extended Producer Responsibility (EPR) law in Vietnam, which mandates that producers are responsible for environmental impact throughout the life cycle of products and packaging, our Vietnam operations organized a focus group session in collaboration with the Packaging Recycling Organization Vietnam (PROVN) to educate over 30 suppliers regarding the new regulations. This is to enhance the supply chain and support sustainable packaging management.

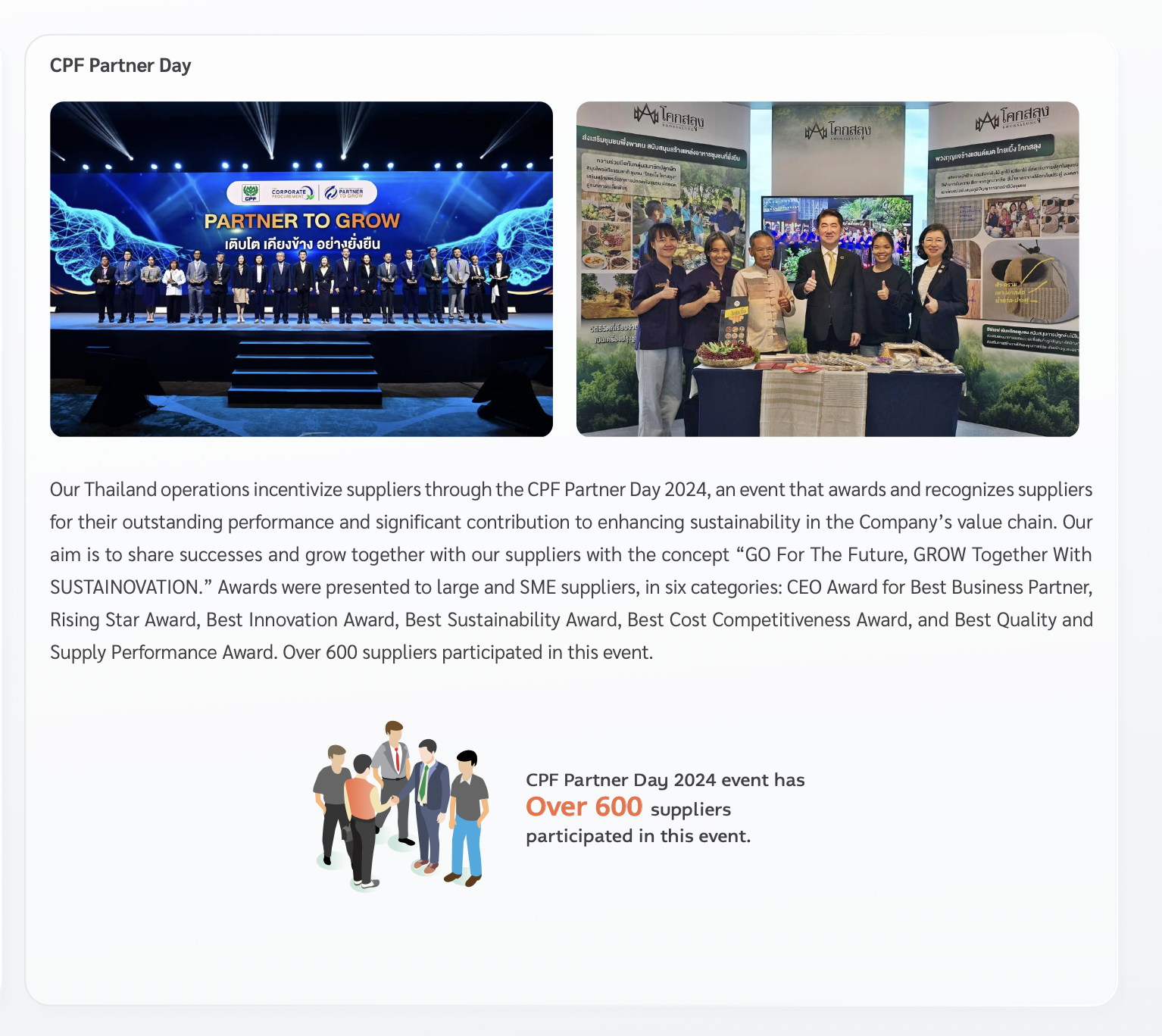

CPF Partner Day

Our Thailand operations incentivize suppliers through the CPF Partner Day 2024, an event that awards and recognizes suppliers for their outstanding performance and significant contribution to enhancing sustainability in the Company`s value chain. Our aim is to share successes and grow together with our suppliers with the concept “GO For The Future, GROW Together With SUSTAINOVATION.” Awards were presented to large and SME suppliers, in six categories: CEO Award for Best Business Partner, Rising Star Award, Best Innovation Award, Best Sustainability Award, Best Cost Competitiveness Award, and Best Quality and Supply Performance Award. Over 600 suppliers participated in this event.